CONFORMAL AND CYLINDRICAL

TYPE-V HYDROGEN TANKS

FERKA designs and manufactures new generation Type-V hydrogen tanks in both conformal and cylindrical configurations. The conformal Type-V tank is a non-circular, prism-shaped high-pressure vessel developed to utilize the available space in vehicles more effectively. It is produced using fibre reinforced polymer composites—mainly high-strength carbon fibre–based thermoset and thermoplastic materials—that withstand an internal service pressure of 72 MPa and a bursting pressure of 157.5 MPa. The innovative design is based on FERKA’s expertise in laminated composites and adhesive bonding technologies.

In addition to the conformal version, FERKA also develops conventional cylindrical Type-V hydrogen tanks without a liner. These tanks are uniquely designed to provide large capacity with minimum end fixtures while maintaining the same high-pressure performance of 72 MPa service pressure and 157.5 MPa bursting pressure.

FUSION BONDING

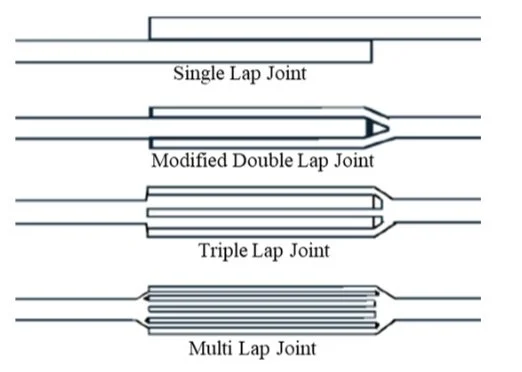

Joining fibre-reinforced polymers is considered to be a critical step in their assembly since traditional joining methods (mechanical fastening and adhesive bonding) introduce some unwanted problems; for example, fasteners add weight to the structure, creates stress concentrations around the fastener holes, and can create paths for galvanic corrosion, while adhesive bonding needs special surface preparation for the surfaces of the structures to be bonded. Besides, adhesive joints are also sensitive to the local stress concentrations and humidity. In the case of thermoplastic composites, there is another joining method, fusion bonding or welding, which overcomes many problems connected to the traditional techniques.

FERKA designs new assembly types that are specific to the thermoplastic composites that have high damage tolerance, excellent corrosion and solvent resistance, high fracture toughness, high impact resistance, good fatigue resistance, low storage cost, and infinite shelf life.

THERMOPLASTIC

WIND TURBINES

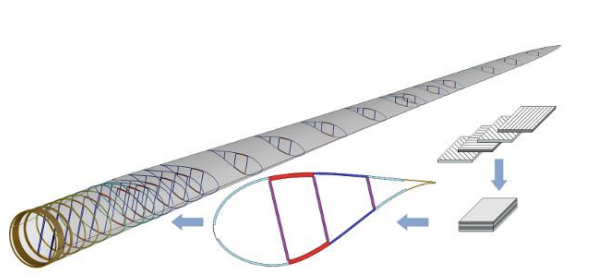

As non-recyclable materials, the thermoset composites are likely to cause environmental pollution, with tons of waste in the future. On the other hand, thermoplastic composite materials are recyclable and reformable, providing ease of fabrication and cost-effectiveness. This brings about a feasibility of healing damaged thermoplastic materials, opposite to the damaged thermoset composites that is quite expensive and complex.

One of the main priority aims of FERKA is to design and fabricate wind turbines using thermoplastic composites.